2-ZONE 열충격 시험 챔버

HIGH TEMP. ZONE

Temp. Range : +60℃ ~ +220℃/(20~85)℃

Temp. Heat-up Rate: ≥ 14℃/min

LOW TEMP. ZONE

Temp. Range : -80℃ ~ +70℃

Temp. Heat-up Rate: ≥ 2℃/min

Temp. Pull-down Rate: ≥ 5℃/min

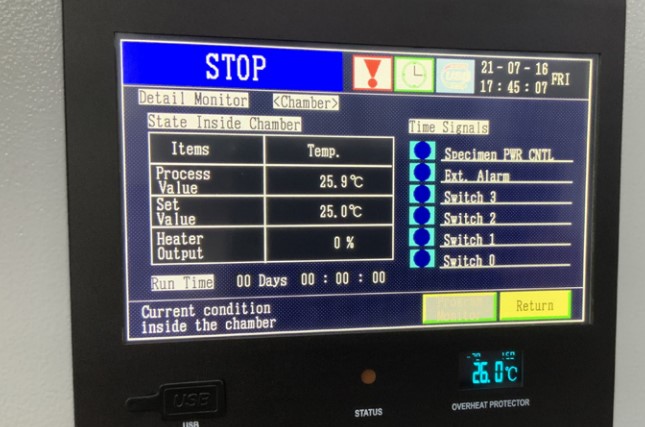

TEST AREA(HANGING BASKET)

High Temp. Exposure Range : ±60℃- +200℃

Low Temp. Exposure Range : -70℃- +70℃

Temp. Fluctuation : 1.0℃

Temp. Deviation : ±2℃(≤ 150℃), ±3℃(> 150℃)

Model : TESTA_e 120TS

견적 요청제품코드: UN5B213